Benefits of RFID Technology

Digital transformation is essential to remain competitive and agile in today's business landscape.

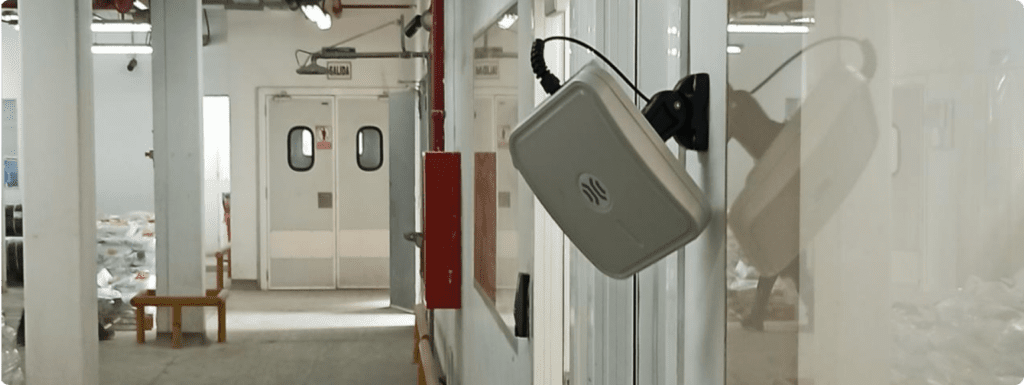

RFID technology serves as a valuable enabler on this transformative journey by providing operational excellence, real-time visibility, data-driven decision-making, enhanced customer experiences, and seamless integration with other digital tools. Companies that leverage RFID effectively position themselves to thrive in the digital age, drive innovation, and meet the evolving needs of their customers and markets. Among the top 10 benefits that collectively make RFID technology a powerful and valuable tool in various industries and applications are

RFID streamlines operations by automating data capture and tracking processes, reducing manual efforts and errors. RFID enables the automation of various processes, from inventory management to supply chain logistics. Automated data capture and tracking of hundreds of items in seconds mean that tasks that were once manual, time-consuming, and error-prone can now be handled by RFID systems. This automation not only saves time but also reduces operational costs and enhances efficiency.

RFID provides real-time data capturing and visibility into inventory, assets, and processes This means that as RFID tags are read by readers, data about the tagged items, assets, or processes is instantly available. This visibility enables better decision-making, reduces stockouts, improves supply chain management, and enhances overall control of operations. It also replaces manual, paper-based processes with digital data streams, facilitating the transition to a digital ecosystem.

RFID virtually eliminates data entry errors, ensuring accurate and reliable data capture. Since RFID tags contain unique identifiers and can store additional information, the risk of human error in data collection and recording is minimized. This accuracy is crucial for making informed decisions and maintaining data integrity.

RFID technology can enhance compliance with industry regulations and security standards. RFID can be used for authentication and counterfeiting prevention, anti-theft purposes and access control, ensuring that only authorized personnel or entities gain access to sensitive areas or information RFID can also be used to track hazardous materials and ensure compliance with safety and environmental regulations.

RFID-generated data can be analyzed to identify process bottlenecks, inefficiencies, and opportunities for improvement. RFID enhances process efficiency in manufacturing by tracking work-in-progress, ensuring the correct components are used, and monitoring equipment maintenance.

RFID enhances supply chain visibility by tracking and tracing goods throughout the entire supply chain. This helps optimize logistics, reduce delays, and prevent losses. Companies can track goods and materials from the manufacturer to the end consumer, allowing them to optimize logistics, reduce delays, and ensure that products reach their destination efficiently. This level of visibility is crucial for supply chain digitalization.

In customer-facing industries like retail, RFID enhances the customer experience by providing real-time inventory tracking and personalized interactions. Customers can receive immediate information about product availability, promotions, and recommendations through digital channels. This level of interaction and personalization fosters digital engagement, enhances customer satisfaction, and drives loyalty, contributing to the company’s digital transformation efforts.

RFID-generated data can be processed and analyzed using advanced analytics tools. This provides actionable insights into operations, customer behavior, and trends. Companies can leverage these insights to make data-driven decisions, optimize processes, and develop more effective strategies.

RFID systems can be remotely monitored and managed, allowing for proactive maintenance and issue resolution. This capability reduces downtime and contributes to the reliability of digital processes.

RFID seamlessly integrates with other digital technologies such as the Internet of Things (IoT) and cloud computing. This integration allows for the aggregation of data from various sources, facilitating comprehensive data analysis and control. For instance, RFID can be integrated with IoT sensors to monitor environmental conditions in a warehouse or supply chain, contributing to data-driven insights and enabling proactive decision-making.

Main Technology Constraints and How to Overcome them

Despite the multitude of applications and benefits provided by the RFID technology, it’s essential to be aware of the technical constraints and complexities that can arise during RFID implementation. To navigate these hurdles successfully and ensure the seamless integration of RFID into your operations, partnering with an experienced integrator, as Invento-RFID, is paramount. An experienced integrator brings valuable expertise to the table, helping you select the right RFID components, design a robust system architecture, and develop strategies to overcome challenges specific to your environment and use cases. With their guidance, you can unlock the full potential of RFID technology, drive digital transformation, and achieve your business objectives effectively. Here a list of constraints and challenges that we can help you overcome:

Read Range

RFID tags have varying read ranges

Choose RFID tags and readers with appropriate read ranges for the application. Active RFID tags are a solution for longer ranges but come at a higher cost and maintenance.

Interference

RF interference can disrupt RFID communication.

Choose RFID tags and readers with appropriate read ranges for the application. Active RFID tags are a solution for longer ranges but come at a higher cost and maintenance. Conduct site surveys to identify potential sources of interference. Use frequency bands with less interference and shielding where necessary.

Line-of-Sight

Obstacles like metal or liquid can obstruct RFID signals.

Position tags and readers strategically to minimize obstacles. Explore RFID tags designed for challenging environments.

Tag Durability

Some RFID tags may not withstand harsh conditions.

Select durable tags rated for the specific environment. Consider encapsulating or protecting tags in challenging settings.

Tag Size and Form Factor

Choosing the right tag size and form factor can be critical.

Assess the available space and select tags that fit the application. Customized tag designs may be necessary.

Scalability

Expanding RFID systems can be complex.

Plan for scalability from the outset. Use standardized hardware and software to ease integration and expansion.

Integration Challenges

Integrating RFID with existing IT infrastructure can be challenging.

Involve IT experts early in the planning stage. Select RFID systems with open APIs for smoother integration.

Read Speed

RFID read speeds may not meet high-speed application requirements.

Select RFID systems designed for high-speed applications. Optimize tag placement and reader settings.

Our subject matter experts will help you address these challenges through careful planning, technology selection, and effective system design. By doing so your company can maximize the benefits of RFID technology while minimizing potential drawbacks.

Comparison to Barcode and other Alternative Technologies

Yes, there are several substitute technologies that can serve similar purposes to RFID (Radio-Frequency Identification) in various applications. The choice of technology often depends on specific use cases, requirements, and constraints. Some notable substitute technologies include:

Barcodes

Barcodes are a widely used alternative to RFID, particularly in inventory management and retail applications. They are cost-effective and easy to implement. However, they require line-of-sight scanning which makes them labor and time intensive and do not offer the same level of automation and real-time data as RFID. Standard barcode labels often can’t withstand tough conditions, like high humidity, drastic temperature fluctuations, exposure to chemicals and sunlight, extremely high temperatures, and rough handling. Barcodes also have limited data capacity and typically store alphanumeric characters in a linear or 2D format while RFID tags can store larger amounts of data, accommodating unique identifiers and additional information. On average RFID read times could be about 25 times faster than barcodes and inventory accuracy could improve from 65% to 95% by eliminating missed barcodes and double-scanned barcodes.

NFC (Near-Field Communication)

NFC technology is used in contactless payment systems, access control, and some inventory management applications. It allows for short-range communication between devices and is often found in smartphones and contactless cards. However, the range of NFC is limited compared to RFID.

QR Codes

GPS (Global Positioning System)

WiFi-Based Tracking:

Biometric Identification

The choice between RFID and substitute technologies depends on factors like range, data capacity, cost, security, and application-specific requirements. In many cases, RFID remains a preferred choice for asset tracking, inventory management, supply chain logistics, and other applications due to its combination of versatility and real-time data capabilities. Our technology experts will be glad to analyze your needs and define if RFID is the best option for your application.